BATTERY REGENERATION

Battery Regeneration

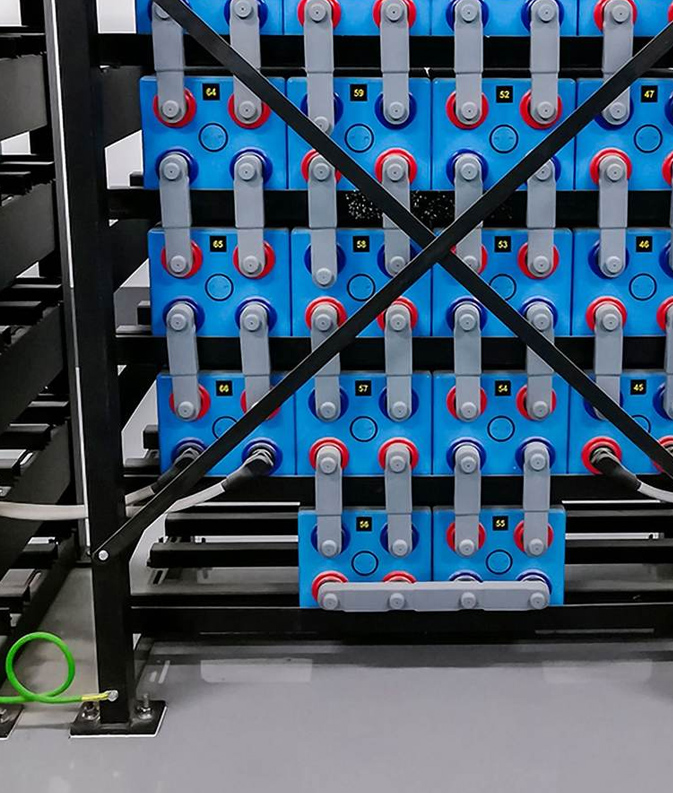

Asia Regen uses state of the art, patented equipment and techniques to reverse many common problems experienced with lead acid and other types of batteries.

The Asia Regen Technology is able to solve the address the sulfation process in the battery and allowing the battery to regain most of its lost capacity. Through our own developed regeneration technology, we are able to reverse the crystallization in the battery and bring the battery back to life.

Better still, our advanced technology is able to restore a battery’s ability to hold a full charge, extending its useful life by as much as 3 years at a much lower cost than would be incurred by replacing the battery.

Every battery is regenerated separately, and there is no loss of regeneration power due to bad cells. We adjust our settings for batteries of different types and in different conditions.

Past experience has shown that we are able to successfully regenerate between 55% and 70% of the batteries brought to our centres, depending on their condition.

ASIA REGEN GENERATION

TECHNIQUES

Batteries lose capacity due to crystallization of the sulfate from the electrolyte.

Asia Regen regenerators are able to reverse the crystallization process through TDLX Wave technology

Batteries are not opened.

Regeneration may be attempted twice, and is considered successful once the battery achieves 85% or more of its original capacity.

All successfully regenerated batteries will be tested in 3 C3 charge-discharge cycles.

Should the battery show a capacity below 85% within these 3 cycles, the regeneration is not considered successful.

After finishing the whole process, all successful batteries will be charged, cleaned and labelled with Asia Regen branding. The batteries are now ‘as good as new’.

Entry date, delivery date, voltage, amperage, IR and capacity are recorded o each battery.

THE STEPS PER

Regeneration

ARE AS FOLLOWS

Recording battery brand, type and barcode at entry

Entry test, which determines the charge capacity of the battery

Regeneration of the battery

Discharging test (C3 test) to determine the capacity after regeneration

Passing the C3 test indicates successful regeneration

One out of every 10 regenerated batteries is selected for a full C10 test

Labelling, cleaning and packaging of the batteries

Batteries delivered weekly to the warehouse of operator with entry and exit records

All batteries will be returned to the operator

Invoices for successfully regenerated batteries are issued periodically in USD

THE ADVANTAGES OF BATTERY

REGENERATION

WHAT TYPES OF BATTERY WE CAN REGENERATE